10-24 Set Screws are essential components in various applications, from securing machine parts to assembling furniture. They provide a reliable and robust fastening solution, thanks to their unique design and threading. This article will delve into the intricacies of 10-24 set screws, exploring their specifications, applications, and best practices for installation and removal.

What is a 10-24 Set Screw?

A 10-24 set screw is a type of headless screw designed to be tightened by applying torque to its internal socket or drive. The “10-24” designation refers to its size and thread pitch. Specifically, “10” denotes the screw’s diameter (in this case, a #10 size, approximately 0.190 inches), while “24” indicates the number of threads per inch. This fine threading allows for precise adjustments and a secure grip. Set screws are typically used to fix a rotating part onto a shaft, preventing slippage or unwanted movement.

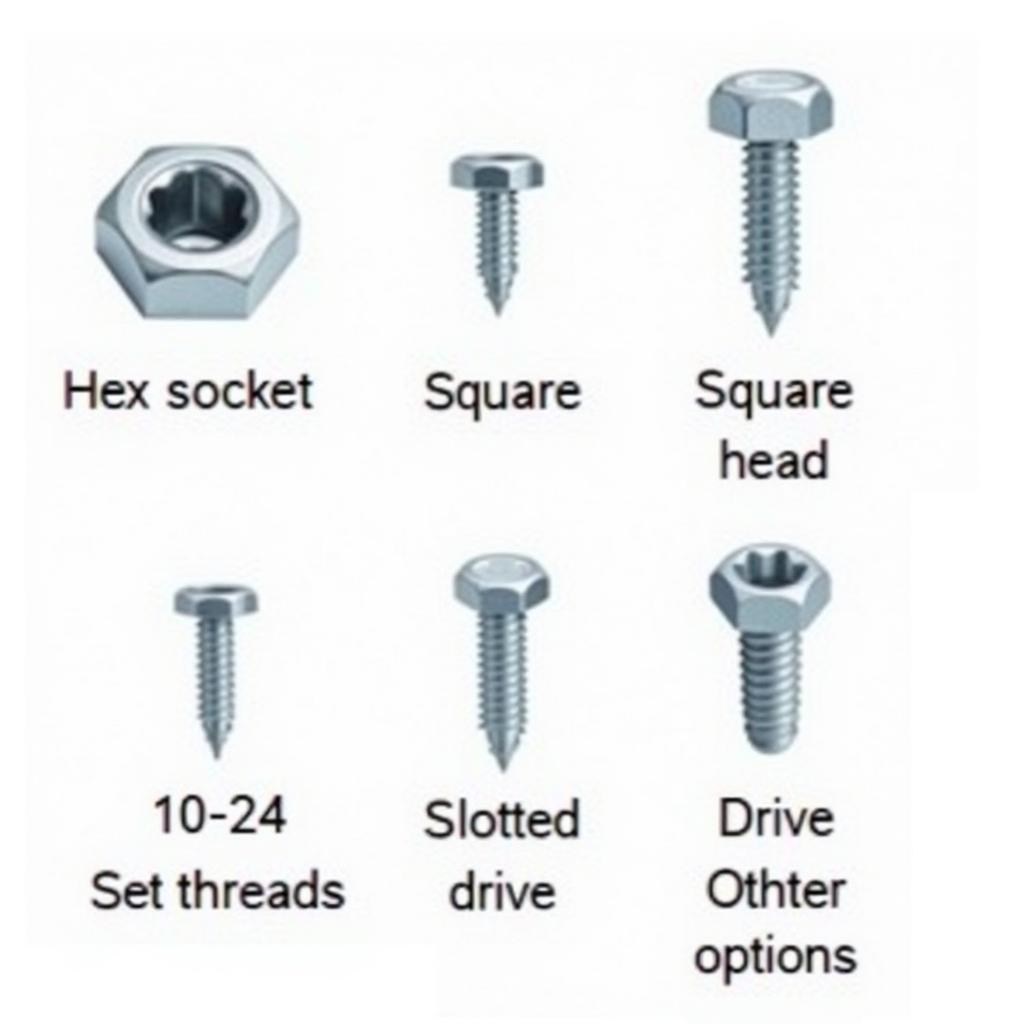

Various types of 10-24 set screws

Various types of 10-24 set screws

Common Applications of 10-24 Set Screws

10-24 set screws are incredibly versatile and find use in a broad range of industries and applications:

- Machinery: Securing gears, pulleys, and collars onto shafts.

- Manufacturing: Assembling various components in production lines.

- Robotics: Fastening joints and other critical parts.

- Electronics: Holding circuit boards and other delicate components in place.

- Furniture: Assembling chairs, tables, and other furniture pieces.

Different Types of 10-24 Set Screws

There are various types of 10-24 set screws, each suited for specific applications:

- Hex Socket Set Screws: The most common type, offering high torque transmission.

- Square Head Set Screws: Suitable for applications requiring a larger bearing surface.

- Slotted Set Screws: Less common now, primarily used for older equipment.

- Button Head Set Screws: Provide a low profile and smooth finish.

Applications of 10-24 set screws in different industries

Applications of 10-24 set screws in different industries

Installing and Removing 10-24 Set Screws

Proper installation and removal are crucial for maximizing the effectiveness of 10-24 set screws:

- Installation: Use the correct size and type of driver to avoid stripping the head. Apply appropriate torque to ensure a secure hold without damaging the components.

- Removal: Use a properly fitting driver and apply steady pressure. If the screw is stuck, use a penetrating oil and allow it to soak before attempting removal.

How to Choose the Right 10-24 Set Screw

Selecting the correct set screw requires careful consideration of several factors:

- Material: Choose a material compatible with the application environment (e.g., stainless steel for corrosive environments).

- Head Type: Select the appropriate head type based on accessibility and torque requirements.

- Length: Ensure the screw is long enough to engage the shaft properly.

- Point Style: Choose the point style based on the application requirements (e.g., cup point for maximum holding power).

“Choosing the correct 10-24 set screw is paramount for ensuring a secure and reliable connection,” says John Smith, Mechanical Engineer at Acme Industries. “Consider the application environment, material compatibility, and head type for optimal performance.”

Conclusion

10-24 set screws are indispensable fasteners in countless applications. Understanding their specifications, types, and best practices for installation and removal is essential for ensuring a secure and reliable connection. Choosing the right 10-24 set screw will contribute to the longevity and performance of your equipment or project.

FAQ

- What does the “10-24” designation mean?

- What are the different types of 10-24 set screws?

- How do I install a 10-24 set screw correctly?

- What materials are 10-24 set screws made from?

- How do I remove a stuck 10-24 set screw?

- What are some common applications of 10-24 set screws?

- How do I choose the right length for a 10-24 set screw?

Common Scenarios and Questions

- Scenario: Stripped screw head. Question: How can I remove a stripped 10-24 set screw?

- Scenario: Screw won’t tighten. Question: Why is my 10-24 set screw not holding?

Further Reading

- Explore other screw types and their applications.

- Learn more about thread pitches and sizes.

Khi cần hỗ trợ hãy liên hệ Số Điện Thoại: 0909802228, Email: doibongda@gmail.com Hoặc đến địa chỉ: 101 Đ. Lý Chiêu Hoàng, Phường 10, Quận 6, Hồ Chí Minh, Việt Nam. Chúng tôi có đội ngũ chăm sóc khách hàng 24/7.