Cold Knife Blades are essential tools in various industries, from medical procedures to industrial cutting applications. Their precise and sharp edges offer clean cuts, making them indispensable for specific tasks. This guide explores the diverse world of cold knife blades, examining their uses, types, and maintenance.

Types of Cold Knife Blades and Their Applications

Cold knife blades are categorized based on their shape, size, and intended use. Understanding these distinctions is crucial for selecting the right blade for the task at hand.

Surgical Cold Knife Blades

In the medical field, cold knife blades are frequently used for precise incisions during surgeries. These blades are typically made of high-grade stainless steel, ensuring sterility and sharpness. Different surgical procedures require specific blade shapes, such as the classic scalpel blade for general incisions or the more specialized blades used in ophthalmic or micro-surgery.

Industrial Cold Knife Blades

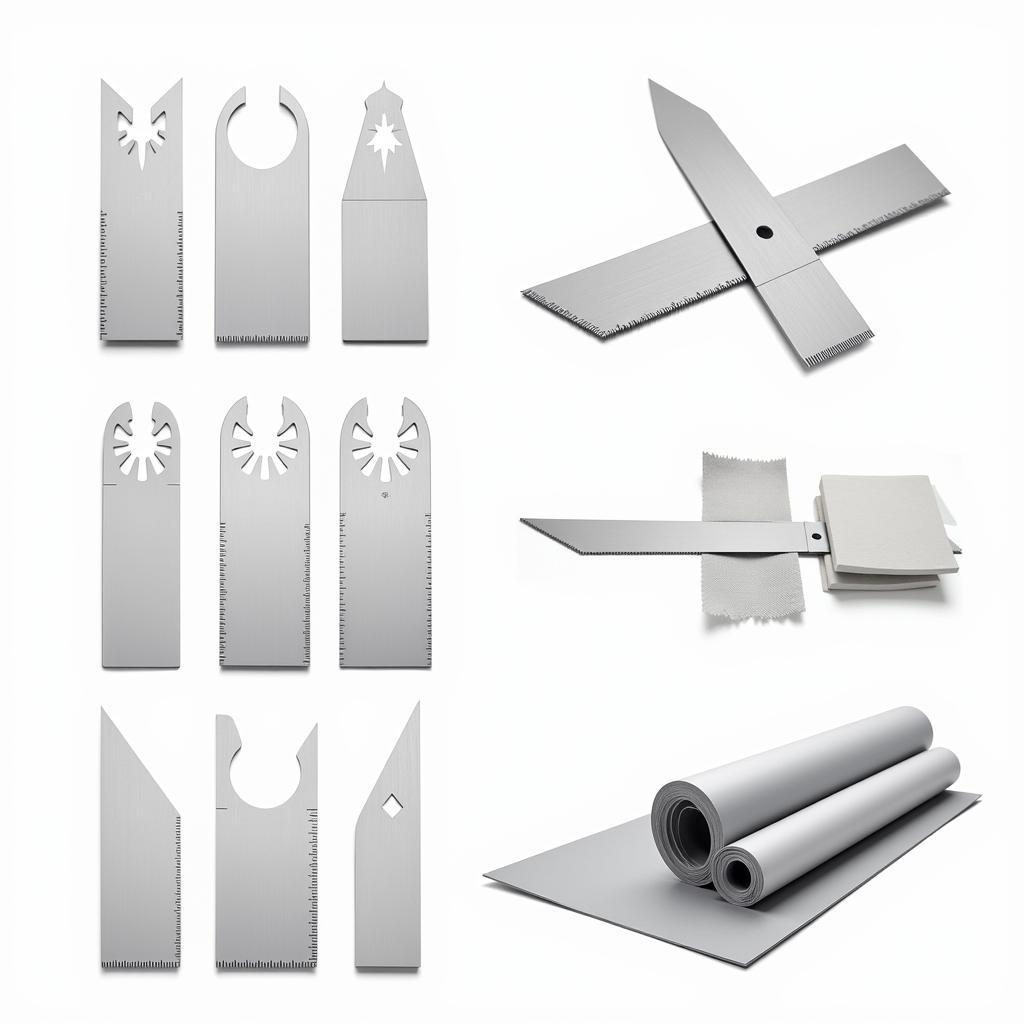

Beyond the medical realm, cold knife blades find application in various industrial settings. These blades, often larger and more robust than surgical blades, are employed in cutting materials like rubber, plastic, and fabric. The specific design and material of the blade depend on the material being cut and the desired precision. For example, blades for cutting fabric might have a serrated edge, while those for cutting rubber might be smoother.

Industrial Cold Knife Blades in Action

Industrial Cold Knife Blades in Action

Maintaining the Sharpness and Longevity of Cold Knife Blades

Proper maintenance is essential to ensure the longevity and effectiveness of cold knife blades. Regular sharpening is crucial to maintain a keen edge, preventing tearing or ragged cuts.

Sharpening Techniques

Different sharpening techniques exist depending on the type of blade. Honing steel is commonly used for maintaining the edge of surgical blades, while industrial blades might require grinding wheels or specialized sharpening tools. Proper technique is crucial to avoid damaging the blade and maintain its intended shape.

Storage and Sterilization

Proper storage is equally important. Blades should be stored in a dry and clean environment to prevent rust and corrosion. In medical settings, sterilization is paramount to prevent infection. Autoclaving is a common method for sterilizing surgical blades.

Selecting the Right Cold Knife Blade: Key Considerations

Choosing the appropriate cold knife blade involves considering several factors, including the material being cut, the desired precision, and the application environment.

Material Compatibility

The material being cut dictates the blade material and design. Harder materials require tougher blades, while softer materials might benefit from finer edges.

Precision Requirements

The level of precision required also influences blade selection. Surgical procedures often demand extremely sharp and precise blades, while industrial applications might prioritize durability and cutting speed over extreme precision.

“Understanding the nuances of each blade type is paramount for achieving optimal results,” says Dr. Nguyen Van A, a leading surgeon at Benh Vien Cho Ray Hospital. “Choosing the correct blade can significantly impact the success of a surgical procedure.”

Conclusion

Cold knife blades are essential tools across various industries, offering precise and clean cuts for diverse applications. Understanding their different types, proper maintenance, and selection criteria is vital for maximizing their effectiveness and longevity. Choosing the right cold knife blade is crucial for achieving the desired results, whether in a surgical setting or an industrial environment.

FAQ

- What are the primary uses of cold knife blades?

- How do I sharpen a cold knife blade?

- What materials are cold knife blades typically made of?

- How do I sterilize surgical cold knife blades?

- What are the different types of cold knife blades available?

- How should I store cold knife blades to prevent damage?

- What factors should I consider when selecting a cold knife blade?

Situations

- Selecting a blade for a specific surgical procedure.

- Choosing the right blade for cutting industrial materials.

- Sharpening and maintaining different types of cold knife blades.

- Storing and sterilizing surgical blades.

Related Articles and Questions

- Explore more about surgical instruments and their uses.

- Learn about different industrial cutting tools and techniques.

- Find out more about blade sharpening methods and best practices.

Khi cần hỗ trợ hãy liên hệ Số Điện Thoại: 0909802228, Email: [email protected] Hoặc đến địa chỉ: 101 Đ. Lý Chiêu Hoàng, Phường 10, Quận 6, Hồ Chí Minh, Việt Nam. Chúng tôi có đội ngũ chăm sóc khách hàng 24/7.