Janet Melt Closure, a technique used in various applications, offers a unique approach to sealing and protecting materials. This guide will delve into the specifics of Janet melt closure, exploring its benefits, applications, and how it compares to other closure methods.

What is Janet Melt Closure?

Janet melt closure involves using heat to fuse or melt the edges of a material together, creating a secure and airtight seal. This process can be applied to a variety of materials, including plastics, fabrics, and composites. The advantage of Janet melt closure is its ability to create a strong, tamper-evident seal without the need for additional adhesives or fasteners.

Benefits of Janet Melt Closure

- Strong and Durable Seals: The melting process creates a homogenous bond, resulting in a robust seal that can withstand pressure and stress.

- Tamper-Evident: Any attempt to open a Janet melt-closed package will be immediately apparent, ensuring product integrity.

- Versatile Application: Suitable for various materials and industries, from food packaging to medical device manufacturing.

- Cost-Effective: Eliminates the need for additional materials like adhesives, reducing overall production costs.

- Environmentally Friendly: Can be used with recyclable materials and reduces waste compared to some other closure methods.

Applications of Janet Melt Closure

Janet melt closure finds its utility in diverse fields. Some prominent examples include:

- Food Packaging: Ensuring food freshness and preventing contamination.

- Medical Device Packaging: Maintaining sterility and protecting sensitive medical instruments.

- Textile Industry: Seaming fabrics and creating waterproof closures.

- Electronics Packaging: Protecting electronic components from moisture and damage.

- Industrial Packaging: Securing and protecting industrial goods during transport and storage.

Comparing Janet Melt Closure with Other Methods

Traditional closure methods, such as adhesives, zippers, and mechanical fasteners, often have limitations. Janet melt closure offers a superior alternative in certain applications:

| Feature | Janet Melt Closure | Adhesives | Mechanical Fasteners |

|---|---|---|---|

| Seal Strength | High | Moderate | High |

| Tamper Evidence | Yes | No | No |

| Versatility | Moderate | High | Low |

| Cost | Low | Moderate | High |

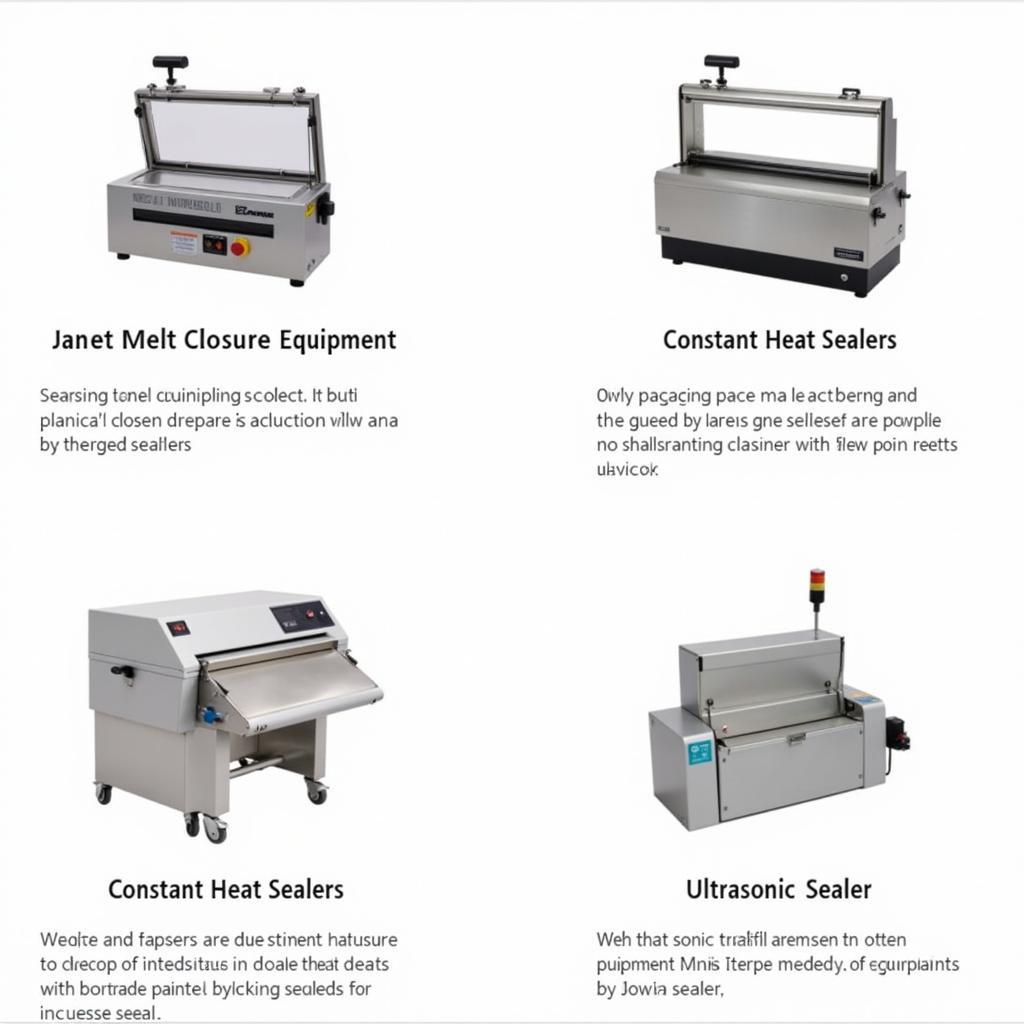

Choosing the Right Janet Melt Closure Equipment

Selecting appropriate equipment is crucial for successful Janet melt closure. Factors to consider include the type of material being sealed, the required production speed, and the desired seal characteristics.

- Impulse Sealers: Ideal for sealing thin plastic films and bags.

- Constant Heat Sealers: Suitable for thicker materials and continuous sealing operations.

- Ultrasonic Sealers: Offer precise and consistent seals for delicate materials.

“Choosing the correct equipment is paramount for optimizing the Janet melt closure process. The material’s thickness and the desired production output are key determinants in this selection,” says Dr. Emily Carter, a leading expert in materials science at the University of California, Berkeley.

Troubleshooting Common Issues

While Janet melt closure offers numerous advantages, certain challenges can arise. Understanding these issues can help optimize the process:

- Inconsistent Seals: This can be caused by uneven heat distribution or improper material preparation.

- Material Degradation: Excessive heat can damage sensitive materials. Careful temperature control is essential.

- Equipment Malfunction: Regular maintenance and proper operation are key to preventing equipment failures.

Different Types of Janet Melt Closure Equipment

Different Types of Janet Melt Closure Equipment

Conclusion

Janet melt closure provides a reliable and efficient sealing solution for a wide range of applications. Its ability to create strong, tamper-evident seals, combined with its versatility and cost-effectiveness, makes it a valuable technique in numerous industries. By understanding the process, its benefits, and the appropriate equipment selection, you can leverage the advantages of Janet melt closure to enhance your products and processes.

FAQs

- What materials are compatible with Janet melt closure?

- What are the advantages of Janet melt closure over traditional methods?

- How do I choose the right Janet melt closure equipment?

- What are some common troubleshooting tips for Janet melt closure?

- Is Janet melt closure environmentally friendly?

- How can I ensure consistent seals with Janet melt closure?

- What are the safety precautions for using Janet melt closure equipment?

Need assistance with Janet melt closure? Contact us at Phone Number: 0909802228, Email: doibongda@gmail.com or visit our address: 101 Đ. Lý Chiêu Hoàng, Phường 10, Quận 6, Hồ Chí Minh, Việt Nam. We have a 24/7 customer support team.