Titan Impact 640 Parts are essential for maintaining and optimizing the performance of your Titan Impact 640 airless sprayer. Understanding these components is crucial for troubleshooting, repairs, and ensuring the longevity of your equipment.

Decoding the Titan Impact 640: An Overview of Key Parts

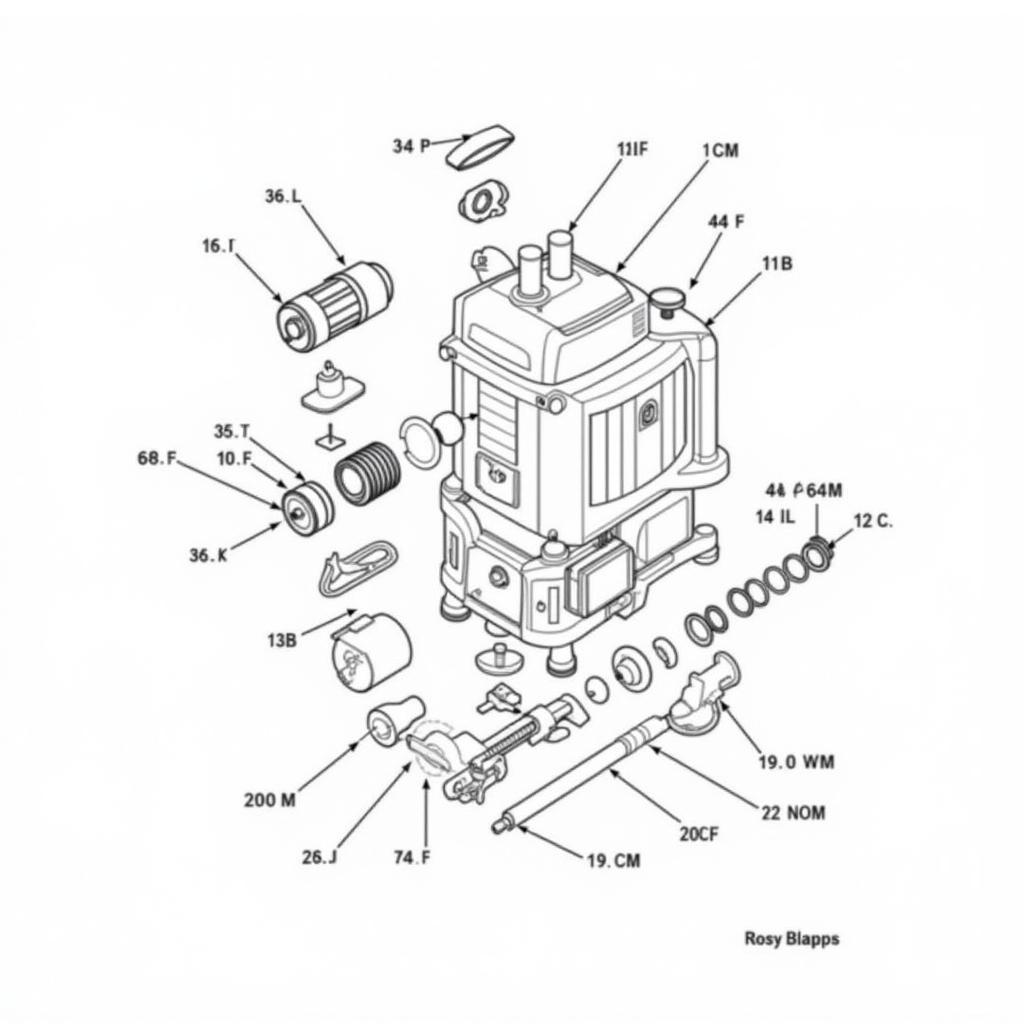

The Titan Impact 640 is a workhorse in the painting industry, known for its power and durability. However, like any machine, regular maintenance and occasional replacement of titan impact 640 parts are necessary. This guide will delve into the essential components, offering insights into their function and importance.  Titan Impact 640 Exploded View Diagram

Titan Impact 640 Exploded View Diagram

Essential Titan Impact 640 Parts: From Pump to Nozzle

Understanding the function of each part is key to effective maintenance. Let’s break down some of the most crucial titan impact 640 parts:

- The Pump: The heart of the 640, responsible for pressurizing and delivering the paint. Regular lubrication and inspection are crucial.

- The Motor: Powers the pump, ensuring consistent paint flow.

- The Filter: Prevents debris from clogging the system, extending the life of other components.

- The Hose: Carries the paint from the pump to the spray gun. Check for cracks and wear regularly.

- The Spray Gun: The final point of contact, dispensing the paint. Proper cleaning and nozzle selection are critical for optimal results.

- Packings: Seals within the pump, preventing leaks and maintaining pressure. These are common wear items and require periodic replacement.

Troubleshooting Common Issues with Your Titan Impact 640

Knowing which part is causing a problem can save you time and money. Here are some common issues and their potential causes:

- Low Pressure: Could indicate worn packings, a clogged filter, or a problem with the pressure regulator.

- Uneven Spray Pattern: Likely a clogged or worn nozzle.

- Motor Not Starting: Could be an electrical issue or a problem with the motor itself.

“Regular maintenance and timely replacement of worn titan impact 640 parts are the best ways to ensure the longevity and performance of your sprayer,” says John Smith, a seasoned painting contractor with over 20 years of experience.

Where to Find Titan Impact 640 Parts

titan 640 parts are readily available online and from authorized dealers. Ensure you purchase genuine parts for optimal performance and compatibility.

Maintaining Your Titan Impact 640: Tips and Tricks

- Regular Cleaning: Clean the sprayer thoroughly after each use to prevent paint buildup and clogging.

- Lubrication: Lubricate the pump regularly as recommended by the manufacturer.

- Inspection: Inspect all titan impact 640 parts regularly for signs of wear and tear.

- Storage: Store the sprayer in a dry and protected location.

“Investing in high-quality titan impact 640 parts and following a regular maintenance schedule is like an insurance policy for your sprayer,” adds Maria Garcia, a product specialist with extensive knowledge of airless sprayers.

Conclusion

Maintaining your Titan Impact 640 with genuine titan impact 640 parts is essential for achieving professional results and extending the life of your equipment. By understanding the function of each component and following proper maintenance procedures, you can keep your sprayer running smoothly for years to come.  Titan Impact 640 Maintenance Kit Contents

Titan Impact 640 Maintenance Kit Contents

FAQs

Khi cần hỗ trợ hãy liên hệ Số Điện Thoại: 0909802228, Email: doibongda@gmail.com Hoặc đến địa chỉ: 101 Đ. Lý Chiêu Hoàng, Phường 10, Quận 6, Hồ Chí Minh, Việt Nam. Chúng tôi có đội ngũ chăm sóc khách hàng 24/7.